Oracle Supply Chain Collaboration

Supply Chain Collaboration is the enablement of accessibility of supply chain information and capabilities to the trading partners in an organization’s supply network. It is the real-time collaborative digital exchange of planning/forecasting, purchasing, inventory fulfillment, and payment transactions between buyers and suppliers to improve traceability and end-to-end visibility of supply chain operations.

Need for Supply Chain Collaboration

Supply chain collaboration is a decisive parameter, especially given the growing emphasis on e-commerce and an omnichannel strategy. It is essential that supply chain managers and procurement professionals collaborate for the below-mentioned impact.

- To improve the product flow

- To improve Customer Satisfaction

- To get end-to-end visibility

- To promote competitive advantage

- To improve supplier relationships

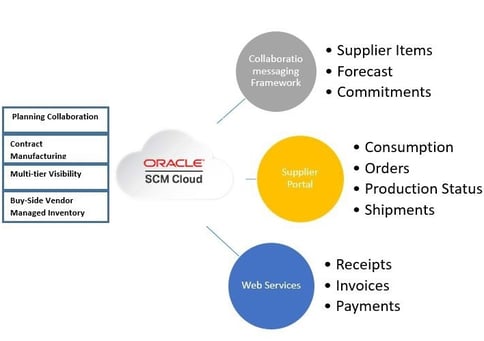

The Oracle SCC cloud has in-built functionalities like:

- Planning Collaboration with planning central – Online order forecast commitment

- Vendor Managed Inventory (VMI) – Pay-on-use, Pay-on-Receipt Models

- Transactional Visibility – Purchase Orders, ASNs, Invoices & Payments review

- Contract Manufacturing – Production and Component usage tracking

Oracle SCC digitally synchronizes the upstream supply from multiple tiers of external organizations, this includes:

- On-hand balances

- POs & Requisitions

- Work order supplies

- Work order component demands

- Work order resources

The holistic visibility across tiers ensures quick actions against upstream supply chain disruptions and it will minimize the downstream disruptions by including this supply information in multi-tier supply plans.

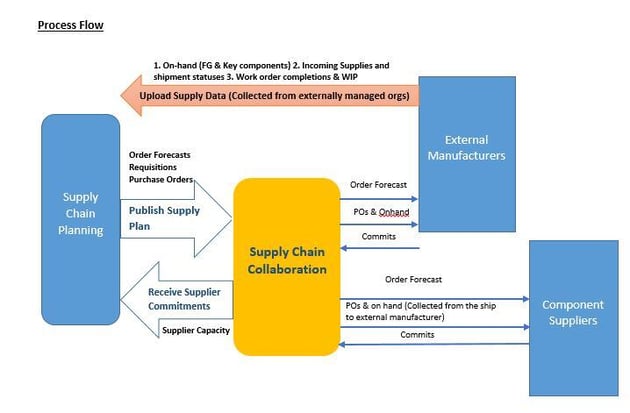

Cloud UI and REST service that allows external manufacturers and enterprise users to upload and monitor the status of each supply data request.

- Initiate supply data upload to an external manufacturer or enterprise user

- Monitor all uploads an enterprise user

- Visibility to all errors that occurred during loading, processing, and collections

- Canceled uncollected supply data requests

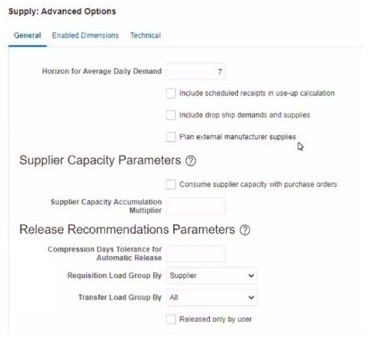

- Model an external manufacturer as an organization and enable plan external manufacturer supplies

- Load data using SCC cloud

- Enable the plan level control in plan options

Internal and External Organizations can be planned in a single supply plan.

- New order type PO demand created to represent the external manufacturing organization demand

- Since PO demands are regular demands, it consumes regular supplies and creates new supply orders if need be, based on the sourcing rule

- Supply orders created cannot be released from external organizations

- Analyze the plan, identify exceptions that put demand at risk, and take actions to improve plant efficiency

Benefits of Supply Chain Collaboration

- End-to-end visibility of inventory across the supply chain

- Holistic views of Product status

- Reduce Just-in-case inventory and reduces inventory cost across the chain

- Enrich strategic relationships with trading partners

- Reliable commits, accurate product status, on-time delivery of customer orders

- Monitor and respond quickly to upstream supply chain issues